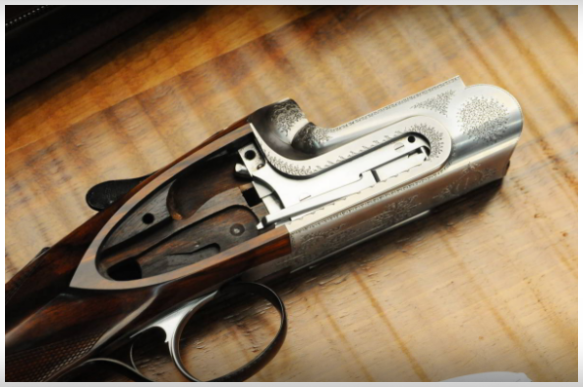

Model IL Sovrapposto

What is the most difficult goal to achieve by building fine guns? Being able to combine functionality with elegance, innovation and tradition. With our new over & under we can claim to be very close to this result.

Judge by yoursef .

The story

The story of our company was always characterized by a constant search for new mechanical and constructive solutions.

Guido followed from the very beginning this difficult road. He realized this being the only way to find his identity as a gunsmith and to compete with his famous peers, whose patents are frequently over a hundred years old. With this in mind he developed his ejector system, the single trigger and his famous sidelock.

These mechanisms weren´t exercises for the sake of creativity or to show off to his ability to develop something different. No, they were robust and simple, allowing to overcome the shortcomings of existing designs, in particular less than stellar reliability.

Following these principles his side by side was created, which is in continuous mechanical and aesthetic evolution. In the nineties, we developed our sidelock double rifle. This process took close to ten years and resulted in a double rifle which incorporated multiple innovative solutions, setting it apart from it´s competition.

After all these accomplishments, one last dream remained, existing only as sketches in a notebook and some milled and filed steel pieces, as a first step to turn this dream into reality.

Then Guido passed away.

At first the dream remained but a dream. However, in our hearts and minds it lived on, until finally the right moment came to proceed. This dream was our over and under named " IL Sovrapposto ". Twelve years have passed, a long gestational period marked by slow progress and episodes of sudden arrest, caused by problems seemingly impossible to solve; solutions were found at times through cooperation of many, at times by individual intuition.

Finally, after numerous designs and prototypes we can proudly say to have created something new, in many respects better, which is not going to revolutionize the history of guns, but incorporates improvements, where everybody said nothing could be invented anymore.

Description

IL Sovrapposto is a sidelock. It has intercepting sears that makes it safe to use with no danger of accidentally shots. It also has our new patented ejector system. The gun can be ordered in 12, 20, and 28 gauge with specially sized actions.

Customers can of course configure the gun with all other features of their choice.

Cocking

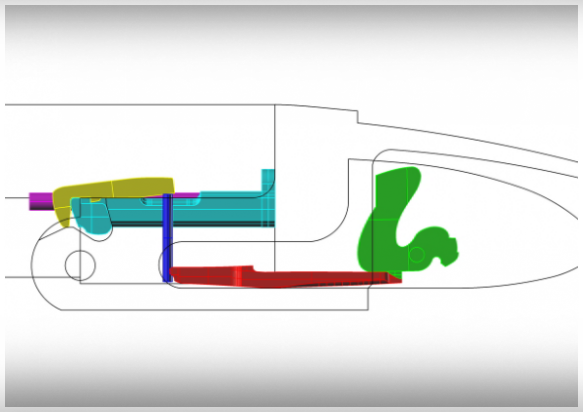

The first innovation in the mechanical configuration of IL Sovrapposto concerns the cocking system.

In spite of having a conventional system of levers and pistons, our gun has a particular innovation in the way the transmission of the cocking force is achieved. Instead of direct contact between forend and pushrod, a u-shaped device rotates around the same pins of the barrels connecting the two. The advantage of such a system consists in the possibility to replace the part in the unlikely case it should wear out. It is designed in a way that minimizes the force necessary to open the gun.

The lockplate

The back-action mainspring lock always had some drawbacks , which nobody has resolved completely.

Those shortcomings are:

- Lack of rebound

- The angle between sear axle and tumbler axle is different from the ideal 90°.

- The length of the mainspring is much shorter compared to a bar action sidelock.

- The bridle is attached by screws and therefore subject to potential movements.

- The difficulty to shape the sideplates elegantly due to the position of the mainspring.

Our sidelock eliminates all these problems:

- It incorporates rebound, thus facilitating the retraction of the firing pins and avoiding difficult barrel opening.

- The particular geometric positioning of the mainspring respects the mentioned ideal angle of 90° and being longer than usual the opening of the barrels is done with ease and the locktime is very short.

- The bridle is integral with the lockplate, guaranteeing absolute stability.

- Finally the positioning of the mainspring allows for an elegant shape of the sideplate, similar to a bar-action lock.

Having elevated in this fashion the back- action sidelock to the level of the bar action sidelock we went one step further.

To all sidelocks there is an intrinsic peculiarity: the sear is attached to the tumbler, whereas the interceptor is ready to catch the tumbler/hammer in case of accidental jarring- out of the notch.

The interceptor is ready to catch the hammer, the probability to accomplish this successfully is not 100%. A violent deceleration of the gun (fall) could therefore lead to accidental discharge.

In our lock we eliminated that possibility: the interceptor rotates in a perpendicular plane to the one in which the sear rotates. A simultaneous movement of interceptor and sear is therefore impossible. But the main innovation consists in the fact that the interceptor is already engaged when the hammer is armed. Only pulling the trigger will cause the gun to fire. The interceptor functions as second sear.

The ejectors

The ejector has always been a difficult component to make due to the wide linear extension of its components.

Only guns of high quality feature it, whereas lesser doubles use the simpler extractor. If we analyze the problems inherent to the correct functioning of an ejector, the first difficulty we encounter is about passing the message that the gun was fired to all components thus enabling them to do their job. The first part that moves during the firing is the hammer, which is located to the back of the action, whereas the ejector is positioned in the forend, at the opposite.

The distance between the two is around 90mm. To somebody not familiar with mechanics and fine guns, this distance appears negligible. But where distances are frequently measured in fractions of millimeters, this value is substantial. Furthermore, this gap is bridged with the help of levers, pins and parts which also serve different purposes in the workings of the gun.

Given the technical difficulties, a lot of different systems are in use. To avoid potential malfunctions associated with the up to now existing ejectors we created a simple and strong one.

The making

All components of IL Sovrapposto are created starting from solid blocks of steel and then are carefully hand fitted and polished.

Each gun is fitted with locks and ejectors designed by us and, on request, also with our patented single trigger mechanism.

Like all of our shotguns, the o&u is made only to order and the customer can specify barrels length, chokes, stock dimensions, triggers configuration, of course, engravings.

The woods are seven years seasoned, oil polished using a long process that needs more than two months to be completed. The barrels are obtained from hand forged blanks, hand polished and rust-blued; the result is as close as possible to perfection.